Selecting the right Fiber Reinforced Plastic (FRP) cable tray manufacturer is crucial for ensuring the quality, durability, and performance of your cable management system. With numerous manufacturers in the market, making an informed decision can be challenging. Chemitech Group, a leading FRP cable tray manufacturer, offers insights into the essential factors to consider when choosing the best manufacturer for your needs.

Quality of Materials and Manufacturing Processes

1. High-Quality Raw Materials: The quality of FRP cable trays starts with the raw materials used. A reputable manufacturer will use high-grade resins and fibers to ensure the trays are durable, resistant to corrosion, and capable of withstanding harsh environmental conditions. Verify the source and grade of materials used by the manufacturer.

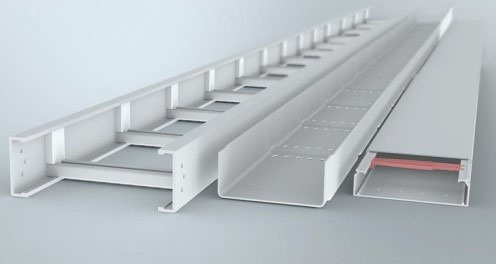

2. Advanced Manufacturing Techniques: The manufacturing process plays a critical role in the final product’s quality. Look for manufacturers that utilize advanced techniques such as the pultrusion process, which ensures consistent quality and strength. Innovative manufacturing methods also allow for the production of customized designs tailored to specific requirements.

Industry Experience and Reputation

3. Established Track Record: Experience matters when it comes to manufacturing high-quality FRP cable trays. Choose a manufacturer with a proven track record in the industry. Established manufacturers are more likely to have refined their processes, ensuring reliability and consistency in their products.

4. Positive Reputation: Research the manufacturer’s reputation within the industry. Look for customer reviews, testimonials, and case studies that highlight their reliability and customer satisfaction. A manufacturer with a strong reputation is more likely to deliver high-quality products and excellent customer service.

Compliance with Industry Standards

5. Adherence to Standards: Ensure the manufacturer complies with industry standards and regulations. FRP cable trays should meet relevant standards such as NEMA, ASTM, and ISO to guarantee safety and performance. Compliance with these standards demonstrates the manufacturer’s commitment to quality and reliability.

6. Certifications: Check for certifications from recognized bodies. Certifications such as ISO 9001 indicate that the manufacturer adheres to stringent quality management practices. These certifications provide assurance that the manufacturer follows best practices in their production processes.

Customization and Flexibility

7. Custom Solutions: Different applications have unique requirements, and a one-size-fits-all approach may not be suitable. Look for manufacturers that offer customization options to meet your specific needs. The ability to design and produce tailored solutions demonstrates the manufacturer’s expertise and flexibility.

8. Range of Products: A diverse product range indicates the manufacturer’s capability to address various industry needs. Whether you require standard FRP cable trays or specialized designs for specific applications, a manufacturer with a broad product portfolio can provide the right solution.

Technical Support and Customer Service

9. Expert Technical Support: Comprehensive technical support is essential for the successful implementation of FRP cable trays. Choose a manufacturer that offers expert guidance and support throughout the selection, installation, and maintenance process. Access to knowledgeable technical staff ensures any issues are promptly addressed.

10. Responsive Customer Service: Excellent customer service is a hallmark of a reliable manufacturer. Ensure the manufacturer is responsive to inquiries, provides clear communication, and addresses concerns promptly. A manufacturer that values customer satisfaction is more likely to build long-term partnerships.

Cost-Effectiveness and Warranty

11. Competitive Pricing: While cost should not be the sole factor, it is important to consider the manufacturer’s pricing. Compare quotes from different manufacturers to ensure you are getting a competitive price without compromising on quality. Be wary of significantly lower prices, as they may indicate subpar materials or manufacturing processes.

12. Warranty and After-Sales Service: A manufacturer that stands behind their products will offer a comprehensive warranty. Check the terms and duration of the warranty to ensure it covers potential defects and issues. Additionally, inquire about after-sales services such as maintenance support and replacement parts availability.

Innovation and Sustainability

13. Commitment to Innovation: The cable management industry is continuously evolving, with new materials and technologies emerging. Choose a manufacturer that demonstrates a commitment to innovation and continuous improvement. An innovative manufacturer is more likely to offer advanced solutions that enhance performance and efficiency.

14. Environmental Responsibility: Sustainability is becoming increasingly important in industrial practices. Look for manufacturers that prioritize environmentally responsible practices, such as using eco-friendly materials and reducing waste in their production processes. A commitment to sustainability reflects the manufacturer’s dedication to long-term environmental stewardship.

Conclusion

Selecting the best FRP cable tray manufacturer requires careful consideration of various factors, including material quality, manufacturing processes, industry experience, and customer support. Chemitech Group, a leading FRP cable tray manufacturer, excels in all these areas, providing high-quality, customized solutions that meet industry standards. By choosing a reliable manufacturer like Chemitech Group, you can ensure the durability, safety, and cost-effectiveness of your cable management system. Make an informed decision and partner with a manufacturer that prioritizes quality, innovation, and customer satisfaction.