The global milling machine market size attained a value of USD 84.26 billion in 2023. The milling machine market is further expected to grow in the forecast period of 2024-2032 at a CAGR of 7.2% to reach USD 157.02 billion by 2032. This growth is being driven by increasing demand across various industries, including automotive, aerospace, defense, and construction equipment. Notably, the Asia Pacific region is the fastest-growing market for milling machines, fueled by rapid industrialization, advancements in manufacturing technologies, and increased investment in infrastructure projects.

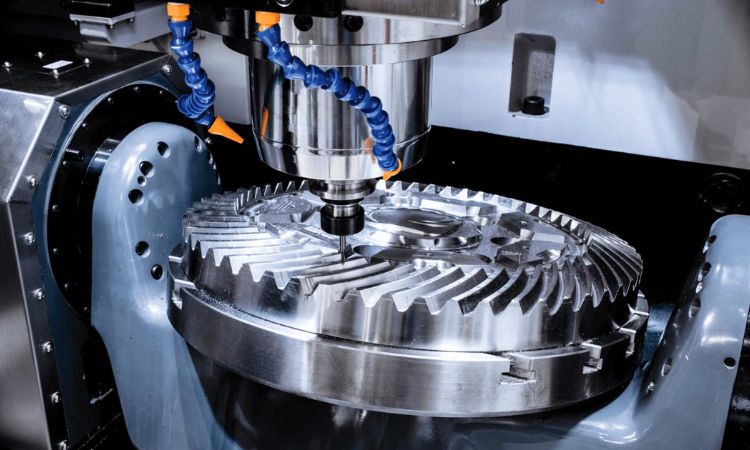

Milling machines play a pivotal role in modern manufacturing processes, enabling precision shaping, cutting, and drilling of various materials, including metals, plastics, and composites. As industries strive for higher efficiency and quality, the demand for advanced milling machines with enhanced capabilities continues to rise. This blog post delves into the key segments of the milling machine market, exploring the market’s growth drivers, segmentation by mechanism, direction, and end use, as well as providing a comprehensive regional analysis and an overview of the competitive landscape.

Market Segmentation by Mechanism

Fraction Rice Milling Machine

Fraction rice milling machines are designed to produce different fractions of rice, such as whole grains, broken grains, and bran, with precision. These machines are crucial in the rice processing industry, where quality and efficiency are paramount. The market share for fraction rice milling machines is substantial, particularly in regions with high rice production, such as Asia and parts of Africa. With the growing demand for high-quality rice and the need for improved processing efficiency, the market for fraction rice milling machines is expected to experience steady growth during the forecast period.

Technological advancements in fraction rice milling machines, such as automation and enhanced precision control, are key trends driving this market segment. Manufacturers are increasingly focusing on developing machines that can process rice more efficiently while minimizing wastage and maximizing yield.

Grind Rice Milling Machine

Grind rice milling machines, on the other hand, are primarily used for grinding rice into flour or powder, which is widely used in various food products. The demand for grind rice milling machines is growing, particularly in regions with a high consumption of rice-based products. These machines are essential in both large-scale industrial settings and smaller, artisanal operations.

The market for grind rice milling machines is expected to grow as consumers continue to demand more diverse rice-based products. Innovations in grinding technology, such as the development of machines that produce finer and more consistent rice flour, are contributing to the market’s expansion.

Market Segmentation by Direction

Vertical Type Mill Rollers

Vertical type mill rollers are widely used in various industries due to their ability to process large volumes of materials efficiently. These machines are commonly used in the production of automotive parts, aerospace components, and construction materials. The vertical design allows for better handling of larger workpieces and offers greater precision in milling operations.

The market share for vertical type mill rollers is significant, driven by their widespread use in industries that require high precision and efficiency. The growth in the automotive and aerospace sectors, particularly in regions like North America and Europe, is expected to fuel the demand for vertical type mill rollers in the coming years.

Horizontal Mill Rollers

Horizontal mill rollers are another key segment in the milling machine market. These machines are often used in applications where stability and consistency are crucial, such as in the production of large metal components for construction equipment and heavy machinery. Horizontal mill rollers are known for their robustness and ability to handle heavy loads, making them ideal for industrial applications.

The market for horizontal mill rollers is expected to grow steadily, with increasing demand from the construction and heavy machinery industries. The ongoing development of infrastructure projects globally is a key factor driving this segment’s growth.

Market Segmentation by End Use

Automotive

In the automotive industry, milling machines are used to manufacture a wide range of components, including engine parts, transmission systems, and body panels. The precision and efficiency offered by advanced milling machines are critical in meeting the stringent quality standards of the automotive sector.

As the automotive industry continues to evolve, with increasing demand for electric vehicles (EVs) and lightweight materials, the market for milling machines in this sector is expected to grow. The adoption of new materials, such as aluminum and carbon fiber, requires advanced milling capabilities, further driving the demand for sophisticated milling machines.

Aerospace and Defence

The aerospace and defense sectors rely heavily on milling machines for the production of high-precision components used in aircraft, spacecraft, and military equipment. The demand for lightweight, durable, and reliable components is driving the growth of the milling machine market in these sectors.

The market share for milling machines in aerospace and defense is expected to increase as governments and private companies invest in new aircraft and defense technologies. Innovations in milling technology, such as the development of multi-axis milling machines, are also contributing to the market’s expansion.

Construction Equipment

Milling machines are essential in the production of construction equipment, such as excavators, loaders, and cranes. The construction industry’s growth, particularly in developing regions, is driving the demand for advanced milling machines that can produce durable and high-quality components.

The market for milling machines in the construction equipment sector is expected to grow as infrastructure projects continue to expand globally. The need for more efficient and reliable construction equipment is fueling the demand for precision milling machines.

Others

Milling machines are also used in various other industries, including electronics, medical devices, and consumer goods. The versatility of milling machines makes them indispensable in a wide range of applications, driving their demand across different sectors.

Regional Analysis

North America

North America is a significant market for milling machines, driven by the region’s strong automotive, aerospace, and defense industries. The demand for advanced manufacturing technologies, coupled with the presence of key industry players, is expected to drive market growth in this region.

Europe

Europe is another major market for milling machines, with a strong emphasis on precision engineering and high-quality manufacturing. The region’s well-established automotive and aerospace industries are key drivers of the market, with countries like Germany, France, and the UK leading the way.

Asia-Pacific

The Asia-Pacific region is the fastest-growing market for milling machines, driven by rapid industrialization and infrastructure development. Countries like China, India, and Japan are witnessing significant demand for milling machines, particularly in the automotive and construction sectors.

Latin America

Latin America is an emerging market for milling machines, with growing demand from the construction and manufacturing industries. The region’s increasing focus on infrastructure development is expected to drive market growth in the coming years.

Middle East and Africa

The Middle East and Africa region are also experiencing growth in the milling machine market, driven by investments in infrastructure and industrial development. The region’s construction industry, in particular, is a key driver of demand for milling machines.

Competitive Landscape

The global milling machine market is highly competitive, with numerous players vying for market share. Key players in the market include DMG Mori, Makino, Haas Automation, and Okuma Corporation. These companies are focusing on technological innovations, product launches, and strategic partnerships to strengthen their market position.

Recent developments in the market include the introduction of advanced milling machines with enhanced capabilities, such as multi-axis machines and automated systems. These innovations are expected to drive market growth and offer new opportunities for industry players.