Molybdenum copper is a unique material that combines the properties of molybdenum and copper, making it useful in various industrial applications. If you’re in Watsonville and need to source this material, there are a few important things you should know.

Understanding what molybdenum copper is, how it’s used, and where to find reliable suppliers can help you make informed decisions for your business.

1. What is Molybdenum Copper?

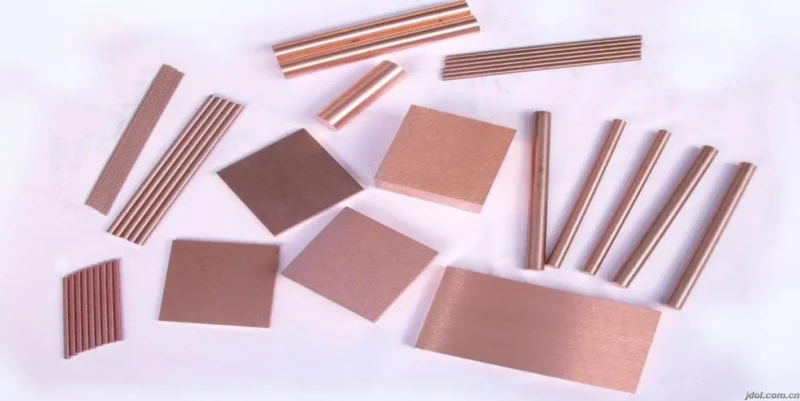

Molybdenum copper is an alloy, meaning it’s a mixture of two metals: molybdenum and copper. Molybdenum is known for its strength, high melting point, and resistance to corrosion. Copper, on the other hand, is well-known for its excellent electrical and thermal conductivity. When combined, these metals create an alloy that retains the best properties of both, making it highly valuable in several industries.

- Strength and Durability

Molybdenum copper is very strong and durable, making it suitable for applications that require materials that can withstand high temperatures and heavy loads.

- Thermal and Electrical Conductivity

The copper in the alloy provides excellent thermal and electrical conductivity, which is essential in electronics and other high-tech applications.

- Corrosion Resistance

Molybdenum adds corrosion resistance to the alloy, making it ideal for use in harsh environments where other materials might degrade over time.

2. Common Uses of Molybdenum Copper

Molybdenum copper is used in a variety of industries, including electronics, aerospace, and power generation. Here are some common applications:

- Electronics

In the electronics industry, molybdenum copper is often used in heat sinks and circuit boards. Its ability to conduct electricity and dissipate heat makes it perfect for managing the heat generated by electronic components.

- Aerospace

The aerospace industry uses molybdenum copper for parts that need to withstand extreme conditions. Its strength and thermal stability make it ideal for components used in engines and other high-temperature areas.

- Power Generation

Molybdenum copper is also used in power generation equipment, particularly in parts that need to handle high temperatures and electrical loads. This includes applications in nuclear reactors and power plants.

- Industrial Machinery

In various types of industrial machinery, molybdenum copper is used for parts that need to resist wear and tear while conducting heat or electricity.

3. Why Source Molybdenum Copper in Watsonville?

Watsonville is a growing industrial hub with access to quality suppliers of materials like Molybdenum Copper Watsonville has several advantages:

- Reduced Shipping Costs: By sourcing locally, you can save on shipping costs, which can be significant for heavy or bulky materials like molybdenum copper.

- Faster Delivery Times: Local suppliers can often deliver materials faster than those located farther away. This can be crucial for meeting tight project deadlines.

- Supporting Local Economy: Purchasing from local suppliers helps support the Watsonville economy, contributing to the growth and prosperity of the community.

- Customized Solutions: Local suppliers may be more willing to work with you to provide customized solutions, such as specific alloy compositions or tailored manufacturing processes.

4. Finding Reliable Suppliers in Watsonville

When sourcing molybdenum copper, it’s important to find a reliable supplier who can provide high-quality materials consistently. Here are some tips for finding the right supplier in Watsonville:

- Research and Reviews: Start by researching potential suppliers online. Look for customer reviews and testimonials to get an idea of their reputation.

- Ask for Samples: Before placing a large order, ask for samples of the molybdenum copper. This will allow you to test the material and ensure it meets your specifications.

- Check Certifications: Make sure the supplier is certified to provide molybdenum copper. Certifications can be a sign of quality and adherence to industry standards.

- Visit the Facility: If possible, visit the supplier’s facility in Watsonville. This can give you a better understanding of their operations and the quality of their products.

- Ask About Lead Times: Inquire about the supplier’s lead times to ensure they can meet your project schedule. Consistent availability is key to avoiding delays in your work.

5. Cost Considerations

The cost of molybdenum copper can vary depending on several factors, including the quality of the material, the quantity ordered, and the current market price of molybdenum and copper. Here are some cost factors to consider:

- Market Fluctuations

The price of molybdenum and copper can fluctuate based on global demand and supply. Keep an eye on market trends to time your purchases for the best prices.

- Bulk Orders

Ordering in bulk can often reduce the cost per unit, making it more economical for large projects. However, be sure you have adequate storage for large quantities.

- Customization Costs

If you require a specific alloy composition or custom manufacturing, this may increase the overall cost. Be sure to discuss these needs with your supplier to get an accurate quote.

- Shipping and Handling

Even when sourcing locally, don’t forget to factor in shipping and handling costs. Some suppliers may offer free or reduced shipping for large orders, so it’s worth inquiring about.

Conclusion

Sourcing molybdenum copper Watsonville offers many advantages, from cost savings and faster delivery to supporting the local economy. By understanding the uses, benefits, and key considerations of sourcing this material, you can make informed decisions that benefit your business and the community. Whether you’re in electronics, aerospace, or any other industry requiring molybdenum copper, Watsonville has reliable suppliers ready to meet your needs. Thank visiting pagetrafficsolution.com