The MAP (Manifold Absolute Pressure) sensor plays an essential role when it comes to keeping your Ford Ranger running smoothly. This small but mighty component helps regulate your engine’s performance by measuring air pressure in the intake manifold. However, like any part of a vehicle, it can experience issues that impact efficiency and overall drivability.

If you’ve noticed unusual behaviour from your Ranger—like poor fuel economy, rough idling, or unexpected stalling—there’s a good chance you may be dealing with some Ford Ranger Map Sensor Issues. But don’t worry; testing and diagnosing this critical sensor is easier than you think!

Understanding the Role of the MAP Sensor

The MAP sensor is crucial for monitoring your vehicle’s engine performance. It measures the pressure inside the intake manifold, providing data to the engine control unit (ECU). This information helps determine how much fuel to inject and when.

In essence, the MAP sensor plays a significant role in optimizing the air-fuel mixture. When you accelerate or change driving conditions, it sends real-time updates to ensure your engine runs efficiently. A well-functioning MAP sensor can lead to improved fuel economy and reduced emissions.

When this sensor is damaged, it can disrupt communication between various systems in your Ranger. The ECU may receive incorrect readings about air density and load, leading to poor performance issues like stalling or misfiring.

Additionally, the MAP sensor contributes to adjusting ignition timing and other vital components that keep your vehicle running smoothly. It’s not just about measuring pressure; it’s part of an interconnected system ensuring optimal operation under different driving scenarios.

Understanding its function gives you insights into how critical this small component is for maintaining your Ford Ranger’s efficiency and reliability on the road. Recognizing potential issues early can save you time and money on repairs.

Common Symptoms of a Faulty MAP Sensor

A faulty MAP sensor can manifest several noticeable symptoms in your Ford Ranger. One of the most common signs is a decrease in fuel efficiency. If you stop at the gas station more often, check this component.

Another indicator is rough idling or stalling when the engine is running. A malfunctioning MAP sensor may not send accurate pressure readings to the engine control unit (ECU), causing irregular air-fuel mixtures that lead to poor performance.

You may also notice an illuminated check engine light on your dashboard. This warning could signal various issues, but if accompanied by other symptoms, it likely points toward a problem with the MAP sensor.

Additionally, unexpected power loss during acceleration can occur. When you press down on the accelerator and don’t feel a corresponding increase in speed, consider investigating potential MAP sensor issues as they directly impact the throttle response.

Abnormal emissions from your exhaust system are worth noting. Increased pollutants could indicate imbalances created by incorrect readings from a failing MAP sensor, affecting combustion efficiency and overall vehicle health.

Tools and Equipment Needed for Ford Ranger Map Sensor

Gathering the right tools and equipment is essential before testing your Ford Ranger Map Sensor. This ensures you have everything to make the process smooth and efficient.

First on the list is a digital multimeter. This versatile tool measures voltage, resistance, and current—key elements in assessing the performance of your MAP sensor. A good quality multimeter makes it easy to read measurements accurately.

Next, you’ll need a vacuum pump or gauge. It helps test for leaks in vacuum lines connected to the MAP sensor. Proper pressure readings are crucial for diagnosing any potential issues effectively.

A basic set of hand tools should also be on standby. Wrenches and screwdrivers will help remove any components that might obstruct access to your MAP sensor or its connections during inspection.

A repair manual specific to your Ford Ranger model can provide valuable insights into wiring diagrams and specifications. It’s an excellent reference point when troubleshooting various components related to Ford Ranger map sensor issues.

With these tools ready, you’re well-equipped for an effective diagnostic session that could save you time and money.

Visual Inspection of the MAP Sensor

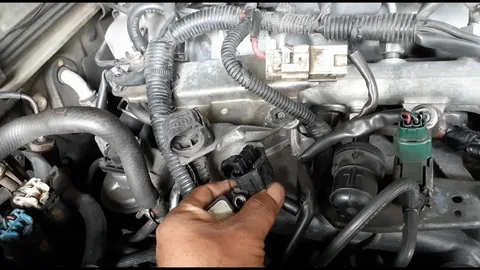

When diagnosing Ford Ranger MAP sensor issues, starting with a visual inspection can save time and effort. This first step allows you to identify any obvious signs of damage or wear. Locate the MAP sensor under the hood, usually near the intake manifold.

Examine the wiring harness connected to the sensor carefully. Look for frayed wires, corrosion, or broken connections that could impact performance. A damaged harness may lead to inaccurate readings or complete failure of the MAP sensor.

Next, inspect the mounting area around the sensor itself. Ensure no oil leaks or foreign substances might interfere with its functionality. Cleanliness is crucial since dirt can disrupt airflow and affect measurements.

Don’t overlook potential physical damage to the sensor housing. Cracks or dents can indicate it has been subjected to extreme conditions or impacts. Such defects often signify internal component issues as well.

Assess surrounding components like vacuum lines and hoses for cracks or loose fittings. These elements work in tandem with your MAP sensor but can also contribute to malfunction if compromised.

Testing the Barina Camshaft Sensor Voltage

Testing the voltage of your Barina Camshaft Sensor is crucial in diagnosing potential issues. This process helps determine if the sensor functions correctly and provides accurate readings to the engine control unit (ECU).

Start by ensuring you have access to a reliable multimeter. Please set it to measure DC voltage, allowing you to check the MAP sensor output accurately. With your Ranger safely parked, locate the MAP sensor, typically found on or near the intake manifold.

Next, carefully unplug the electrical connector attached to the sensor. Insert one probe of your multimeter into the signal wire terminal while connecting another probe to the ground. You must maintain a secure connection for accurate readings.

With everything set up, start your engine and let it idle. Observe any voltage changes on your multimeter display; at idle speed, you should see a reading between 0.5 and 1 volts depending on altitude and other factors affecting atmospheric pressure.

As you gradually increase RPMs, watch how these values change. A steady rise indicates proper functionality, while erratic signals or no change may point toward possible faults in either the wiring or the MAP sensor itself.

Checking the Sensor’s Response to Engine Changes

Ensure your Ford Ranger is running to check the MAP sensor’s response to engine changes effectively. A warm engine will give you a more accurate reading than a cold one. Observe how the MAP sensor behaves in real-time as the vehicle idles.

Next, gently accelerate or rev the engine while monitoring your scanner or multimeter readings. The voltage output from the MAP sensor should change accordingly with throttle input. Typically, as you increase RPMs, expect an increase in voltage—this indicates proper function.

If readings fluctuate little to no during acceleration, this could indicate issues with the sensor itself. Pay attention not just to numbers but also to any delay between changes; sluggish responses can signal trouble ahead.

Additionally, consider creating some load on the engine by turning on accessories like headlights or AC while accelerating again. This added demand should further influence MAP readings and help confirm if everything is functioning correctly.

Keep in mind that these checks are vital for pinpointing specific Ford Ranger map sensor issues early on before they escalate into more severe problems.

Inspecting the Vacuum Lines and Connections

Inspecting the vacuum lines and connections is crucial in diagnosing Ford Ranger MAP sensor issues. Vacuum leaks can significantly affect engine performance, leading to erratic readings from the MAP sensor. Ensuring these lines are intact will help rule out other potential problems.

Start by visually examining all visible vacuum hoses connected to the intake manifold and MAP sensor. Look for cracks, splits, or any signs of wear that could lead to air leaks. Even a small crack can cause significant issues with pressure readings.

Next, check if all connections are secure. Loose fittings might introduce unmeasured air and mislead your diagnostic efforts regarding the MAP sensor’s functionality. Gently tug on each hose connection; they should feel tight without any give.

Following up with an auditory inspection while the engine runs is also wise. Listen for hissing sounds, often indicating a leak in a vacuum line. If you hear anything unusual, note that it may point directly toward where repairs are needed.

Ensure there are no obstructions within the lines themselves. Debris or foreign objects can restrict airflow and throw off pressures detected by your MAP sensor, complicating diagnostics even further.

Interpreting the Astra Camshaft Sensor Test Results

Once you’ve completed your tests, it’s crucial to interpret the results accurately. Start with the voltage readings from the Astra Camshaft Sensor. When connected properly, a healthy MAP sensor typically shows a voltage range between 0.5 and 4.5 volts at idle. If your measurements fall outside this range, it may indicate a problem.

Next, assess how well the sensor responds to engine changes during testing. Revving the engine should cause noticeable fluctuations in voltage output from the MAP sensor. If little to no change, that’s a red flag signalling potential failure.

Check for consistency in readings across multiple tests as well. Inconsistent results can point toward intermittent faults, often more challenging to diagnose but equally important to address.

You also want to consider external factors affecting these results—like vacuum leaks or faulty wiring—that could lead you astray regarding the actual state of your MAP sensor.

If all other components seem functioning, yet you still experience issues like poor fuel economy or performance problems in your Ford Ranger, pinpointing a faulty MAP sensor becomes essential for effective repairs and improvements down the road.

Conclusion

Diagnosing Ford Ranger MAP sensor issues can seem daunting, but it’s manageable with the right approach and tools. Understanding how the MAP sensor functions is crucial for troubleshooting effectively. Knowing its role helps pinpoint problems accurately.

By recognizing common symptoms of a faulty MAP sensor, such as rough idling or poor fuel efficiency, you’re already ahead in identifying potential issues. These indicators often lead to deeper investigations that can save time and money.

Conducting thorough tests using proper equipment makes a significant difference in diagnosing the problem correctly. Whether checking voltage or inspecting vacuum lines, each step provides valuable insights into your vehicle’s performance.

Don’t overlook visual inspections—they reveal obvious signs of wear or damage that might be affecting functionality. A simple look can sometimes uncover hidden concerns before they escalate into larger problems.

Regular maintenance checks on components like the MAP sensor are essential for keeping your Ford Ranger running smoothly. Staying proactive prevents costly repairs down the line and enhances the overall driving experience and safety on the road.

FAQs

What does a MAP sensor do in my Ford Ranger?

The MAP sensor measures the air pressure within the intake manifold. This information helps your engine control unit (ECU) optimize fuel delivery and ignition timing for better performance and efficiency.

How often should I replace my MAP sensor?

While there’s no set timeline for replacing a MAP sensor, signs like poor fuel economy or rough idling may indicate it’s time for a check-up. Regular inspections during maintenance schedules can also prevent unexpected failures.

Can I drive with a faulty MAP sensor?

Driving with a malfunctioning MAP sensor isn’t advisable. Doing so could lead to increased emissions, reduced fuel efficiency, and even damage to other engine components over time.

| Related Business Listings |

| Contact Directory |

| Local Business Profiles |