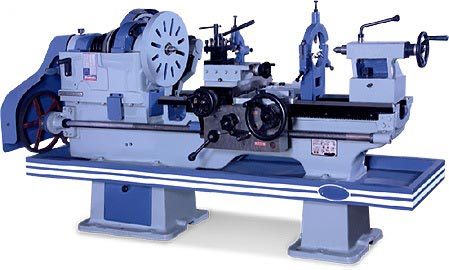

Lathe machines are a staple in manufacturing and metalworking, known for their ability to shape materials with precision. However, operating these machines comes with its own set of safety requirements, especially in a busy industrial environment. Leader Machine Tools, a trusted name in machinery manufacturing in India, is dedicated to promoting the safe and efficient use of Lathe Machine in India. Below, we’ve outlined essential safety tips that operators should always keep in mind to minimize risks and maximize productivity.

1. Understand the Machine: Knowledge is Power

Every operator must thoroughly understand the lathe machine they’re working with. Different lathe machines have unique functionalities, and without proper knowledge, even experienced operators can make mistakes. Leader Machine Tools provides detailed manuals and training resources with each machine, which operators should study carefully. Familiarize yourself with the control panel, switches, speed options, and emergency stop mechanisms.

2. Inspect the Machine Regularly

Before beginning any operation, inspect the lathe machine for any visible wear, damage, or loose parts. Regular inspections prevent accidents that could occur due to worn-out components. Check that the tool post, tailstock, and chuck are all secure. If anything appears damaged or out of place, report it to the supervisor or maintenance team before proceeding.

3. Wear Appropriate Personal Protective Equipment (PPE)

Using the right personal protective equipment is crucial. PPE for lathe machine operation typically includes:

- Safety glasses or a face shield: Protects against flying debris or sparks.

- Gloves: Non-slip gloves that don’t snag easily.

- Ear protection: Necessary in high-noise environments to prevent hearing damage.

- Steel-toe boots: Protect feet from dropped parts or tools.

Leader Machine Tools advises operators to invest in high-quality PPE that meets safety standards in India, as this can significantly reduce injury risks.

4. Dress Appropriately

Loose clothing, long hair, and jewelry can easily become entangled in the spinning parts of a lathe machine, leading to serious injuries. Ensure clothing fits well, roll up sleeves, tie back long hair, and remove any jewelry before operating the lathe. Aprons are recommended for additional protection, as they add a protective layer between you and the machine.

5. Use Proper Clamping and Positioning Techniques

Securely clamp the workpiece and tool in place before turning on the lathe. Ensure that the tool is positioned correctly, and double-check that it is stable and in alignment. Unsecured or misaligned tools can lead to severe accidents, damaging the lathe or the workpiece and potentially injuring the operator. Leader Machine Tools provides lathes with precision-built clamps and supports to make this process as smooth and secure as possible.

6. Follow Speed Limits and Settings

One of the most common mistakes operators make is setting the lathe to an incorrect speed. Each material requires a specific speed range for safe and effective cutting. Consult the machine’s manual or reference charts provided by Leader Machine Tools to identify the correct settings based on material type and job requirements. Never exceed the recommended speed limits, as this can cause excessive vibration, loss of control, and breakage.

7. Keep the Work Area Clean

A cluttered workspace is a hazardous one. Always keep the area around the lathe clean and organized, with tools stored in their designated places. Metal shavings, oil, or coolant spills can be slippery and lead to falls or cause debris to enter the machine. Clean the work area regularly, and dispose of any waste materials in designated containers. Leader Machine Tools’ lathe machines are designed for easy maintenance and cleanup, helping operators maintain a safe workspace.

8. Be Mindful of the Chuck Key

Leaving the chuck key in the chuck is a common mistake with potentially deadly consequences. If the lathe is turned on with the chuck key still inside, it can fly out at high speeds, causing serious injuries to the operator or others in the vicinity. Develop a habit of removing the chuck key immediately after adjusting the chuck and before powering on the lathe.

9. Stay Focused and Avoid Distractions

Operating a lathe requires full attention, as even a brief distraction can lead to costly mistakes. Avoid using your phone or engaging in unrelated conversations while the lathe is in operation. Leader Machine Tools encourages operators to maintain focus during every step of the machining process, as being attentive significantly reduces the risk of accidents.

10. Use Proper Feeding Techniques

Avoid manually pushing the tool toward the workpiece. Instead, let the machine do the work. Forcing the tool can lead to uneven cuts, damage the workpiece, and even break the tool. Make gradual adjustments to the tool’s position and allow the lathe’s automated feed to guide the process.

11. Know the Emergency Stop Procedure

Despite all precautions, emergencies can happen. Make sure you know the location and function of the emergency stop button on your lathe machine. In the event of an unexpected issue, being able to stop the machine immediately can prevent injuries and damage. Leader Machine Tools ensures that all machines come with accessible and easy-to-use emergency stop mechanisms for this reason.

12. Turn Off the Machine When Not in Use

Never leave a running lathe machine unattended. Turn it off completely if you need to step away, even for a moment. Leaving it running unsupervised can lead to accidents, especially if other operators are unaware of its status. Leader Machine Tools emphasizes the importance of this safety tip in their operational training, as it’s one of the simplest yet most effective ways to avoid mishaps.

13. Regularly Maintain the Machine

Proper maintenance is essential for a safe Lathe machine manufacturer in india Schedule regular inspections and servicing to keep the machine in optimal condition. Regularly lubricate moving parts, check electrical connections, and replace worn components. Leader Machine Tools provides post-purchase support and recommends routine maintenance to extend the life of your machine and ensure safety.

14. Get Professional Training

One of the most effective ways to ensure safety is to receive proper training from experienced professionals. Leader Machine Tools offers training sessions for their machines, equipping operators with the necessary skills and knowledge to operate lathes safely. Understanding best practices, tool handling, and machine features under the guidance of experts makes a significant difference in reducing workplace accidents.

Conclusion

Safety should always be the top priority when operating lathe machines. By following these safety tips and best practices, operators can ensure a secure working environment and get the best performance out of their machines. Leader Machine Tools, committed to supporting India’s manufacturing industry, provides high-quality, reliable lathe machines with a focus on user safety and operational efficiency. Whether you’re a seasoned professional or new to machinery, adhering to these guidelines is crucial for a safe and productive workspace.

Investing in quality equipment from Leader Machine Tools and following these tips can help operators avoid common pitfalls, reduce accidents, and ultimately, foster a culture of safety in India’s thriving industrial landscape.